Injection Molding High-Density Polyethylene (HDPE)

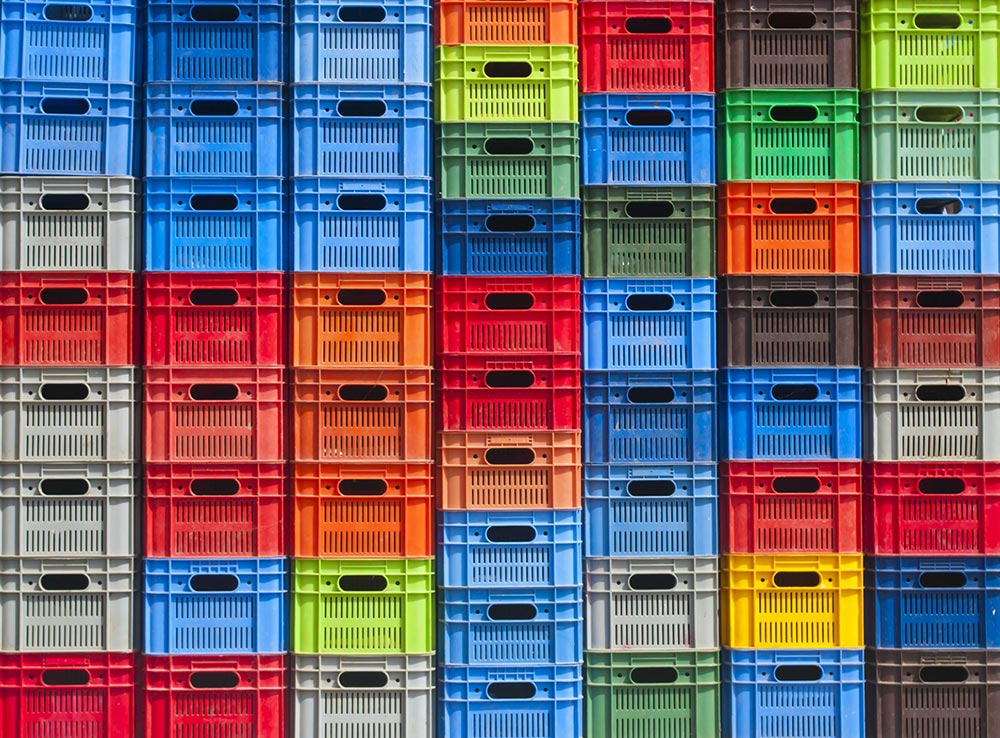

Applications for HDPE injection molding resin include pails, crates, tote boxes, housewares, automotive, hardware and sporting goods.

Virgin High-Density Polyethylene (HDPE) Plastic Resin Pellets we offer:

| Material Type | Application | Form | Melt Index (ASTM D1238) | Density (ASTM D1505) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Injection Molding | Pellets | 5.0 | 0.955 |

| High-Density Polyethylene (HDPE) | Injection Molding | Pellets | 6.0 | 0.960 |

| High-Density Polyethylene (HDPE) | Injection Molding | Pellets | 20.0 | 0.955 |

Virgin High-Density Polyethylene High-Molecular Weight (HDPE-HMW) Plastic Resin Pellets we offer:

| Material Type | Application | Form | Melt Index (ASTM D1238) | Density (ASTM D1505) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE - HMW) | Film | Pellets | 0.05 | 0.950 |

| High-Density Polyethylene (HDPE - HMW) | Pipe | Pellets | 0.07 | 0.955 |

Packaging

Our material is packaged in 25 kg bags, Gaylord boxes and super sacks. Our product is quality tested and sold based on the physical properties, including melt flow and density. At Birch Plastics, we sell our virgin plastic resin pellets in truckload, and less than truckload quantities, and always out of our Houston facility.

About High-Density Polyethylene (HDPE)

HDPE is the sturdiest and most inflexible type of polyethylene within polyethylene applications. Its sturdy and moderately robust character can be used for a wide range of applications. HDPE is defined by having a density greater than or equal to .941 g/cm3. High-density polyethylene (HDPE) represents the most common portion of the polyethylene applications. HDPE offers excellent impact resistance, lightweight, low moisture absorption and high tensile strength. Additionally, HDPE is also nontoxic and non-staining.